From the “way-back machine” is an article that ran in TDR Issue 19 in 1998. Much of it is still relevant. it starts off with a question from a TDR member.

Q. I have one simple question—maybe I won’t get an easy answer. Where should my transmission temperature sensor be located, short of having it welded in the transmission pan? The transmission temperature gauge installed in my ’95 Turbo Diesel with automatic transmission was installed by a major RV accessories company. I had some misgivings regarding where they installed the sensor, so I called around. I talked to four different Dodge dealerships and all were adamant that it should go in the line where the high-temperature sensor is located. Others have insisted that it go in the return line to transmission after the oil has been cooled.

Right now, I’m confused. It would seem that there should be an optimum line for locating the sensor. Both scenarios seem to have a logical argument for them. I realize that the logical place would be to have it welded in the bottom of the pan, but most installers prefer not to do that.

Any enlightenment or help on this question would be greatly appreciated. I would like to have the feeling that I am reading the proper temperatures.

A. if you ask 100 people, you will get 100 different answers. The answer is that the location doesn’t really matter. With a transmission temperature gauge you’re watching for a high trend. My answer is to use a Geno’s Garage temperature gauge with a dipstick sensor, thus effectively locating the sensor in the “pan” of the transmission oil.

We’ve done articles on setting a baseline for performance. Do you have a high temperature problem that warrants that fancyfin, extra-capacity, made of aluminum, heat dissipating, transmission pan? That’s why the dipstick sensor is so practical, for it does not require any holes in the pan, welding or brazing of fittings—no opportunities for owner-installed items that could leak. Install a dipstick unit with your stock pan, establish a baseline and make an informed decision about the purchase of the extra-capacity pan. Should you choose the extra-capacity pan your temp sending unit stays in the same location to help you determine the before versus after merits. So that you don’t think I’m trying to sell gauges, let’s reference Motorhome magazine’s column, “Performance/Mileage” written by John Geraghty. John’s response to a customer’s question is as follows:

“A transmission oil temperature gauge is not a necessity when adequate cooling is assured; however, monitoring the fluid temperature in the transmission pan does provide useful information relative to the transmission’s standard pattern of operation.

“I prefer to locate the temperature sender in the transmission pan. This provides a more consistent overall temperature reading than does a sender location in the return line from the oil cooler. Maximum oil temperature in the pan should not exceed 250 degrees F. If the temperature rises above this point, pull over and fast idle the engine in Neutral or Park for a few minutes to cool the transmission fluid.”

The advantage to subscribing to numerous magazines is the abundance of information. Discerning accurate versus inaccurate is often difficult. One cannot help but note the disparity between column A (Off-Road, February ’98, page 62) and column B (Sports Truck, January ’96, page 15). One also would like to know where the temperature readings are taken. Neither article noted the location of the sensor.

Transmission Life Expectancy Chart

| A | B | Notes from article B | |

| 175° | 240,000 | 100,000 | Optimal heat level for oils, seals, clutches and plates. |

| 195° | 120,000 | 50,000 | |

| 220° | 50,000 | 20,000 | Oil viscosity begins to break down. |

| 240° | 25,000 | 10,000 | Varnish begins to form. |

| 260° | 15,000 | 5,000 | Seals harden. |

| 295° | 4,000 | 1,500 | Plates slip. |

| 315° | 2,000 | 800 | Seals and clutches burn out. |

However, it matters not which column is accurate The point in presenting the data is to show the negative effect of temperature. An interesting conclusion from both columns: From 220° to 240° to 260° as the temperature increases by 20°, the life expectancy is cut approximately in half.

Also note that above 195° the life expectancy drops dramatically.

ANOTHER TRANSMISSION TIP

When installing a new automatic transmission pan gasket, or almost any other gasket which doesn’t want to stay in place during the mating of the gasketed parts, spread a light coat of chassis grease on one surface and place the gasket on it. The gasket will then stay in place and be lined up for the rest of the installation.

CHANGE “ALL” THE FLUID

As odd as it may sound, my local Friday newspaper is a good source for truck tips. In the Friday edition, they have a section called “Wheels” that features “Car Talk” by Tom and Ray Magliozzi. If you’ll disregard the references to the ’92 Toyota Camry and the 30K maintenance internal, you may find the column entertaining and perhaps enlightening.

Dear Tom and Ray: I recently took my 1992 Toyota Camry with 67,000 miles to the dealer for an oil change. I asked that the fluids be checked. The service advisor told me that the transmission fluid was at its proper level and was “fairly” clean. I maintain the car religiously and had a complete transmission service at 60,000 miles, so I don’t understand why the fluid was only “fairly” clean. Why not “completely” clean?

The service advisor stated that only about half of the fluid can be drained during transmission service, and that if I really wanted it totally clean, I should change the fluid two or three more times. I understand that changing the transmission fluid every 30,000 miles is adequate. Is it?

Paul (your faithful reader)

Tom: Yes, it is. The dealer is right that you can’t get all of the transmission fluid out simply by removing the drain plug or by dropping the pan. When you drain it, there is still fluid in the torque converter and some of the passages.

Ray: If you really wanted to change “all” the fluid, you would have to drain it several times.

Tom: But it’s really not necessary. Changing most of the fluid every 30,000 miles is good enough. Some manufacturers now tell you not to bother changing the transmission fluid at all.

Ray: I think the real problem here was semantic. He told you your fluid was “fairly” clean. He should have just said “clean,” which it was in the overall scheme of things.

Change All of the Transmission Fluid

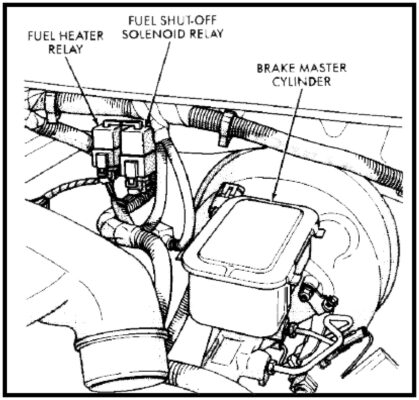

If your transmission pan doesn’t have a drain plug (read: your very first transmission fluid change), to provide for an easy fluid change, or if you want to change all of the fluid (net change 10 – 12 quarts) try this method. Pinch-off and then disconnect the return-to-transmission, transmission cooler line from the radiator (location: driver’s side of vehicle; bottom corner of radiator just beside the radiator coolant/fluid drain petcock). Of the two transmission lines, this is the outboard line and (thankfully) it is the easily accessible line.

Take the ½” rubber hose and bend it upward to prevent fluid drainage.

Next, connect a three-foot length of ½” rubber hose to the metal flare coming from the radiator. Feed your rubber hose into a five-gallon container. With the truck in Park, depress the emergency brake, chock the tires, then start the engine. Shift the truck into Neutral***.

ATF will begin flowing into the container. Once the flow begins to dwindle, immediately kill the engine. This technique will yield 10 – 12 quarts of fluid. Re-attach the ½” rubber hose/cooler line to the metal flare from the radiator. Continue with your transmission maintenance (filter change?). Refill the transmission with new fluid before restarting the engine. And be sure to safely dispose of the old ATF.

(Front of vehicle.)

After refill, the correct procedure for checking your transmission fluid is outlined in your Owner’s Manual.

· The vehicle must be on level ground.

· The engine should be running at curb idle speed for a minimum of 60 seconds.

· Fully apply parking brake.

· Place the gear selector briefly in each gear position ending with the lever in N (Neutral). ***

· Remove the dipstick and determine if the fluid is hot or warm. Hot fluid is approximately 180° F (82° C) which is the normal operating temperature after the vehicle has been driven at least 15 minutes. The fluid cannot be comfortably held between the finger tips. Warm is when fluid is between 85° – 125° F (29° – 52° C).

· Wipe the dipstick clean and reinsert until seated. Remove dipstick and note reading.

a) If the fluid is hot, the reading should be in the crosshatched area marked “OK.”

b) If the fluid is warm, the reading should be between the two holes. If the fluid level indicates low, add sufficient fluid to bring to the proper level.

· Fluid is added through the dipstick tube.

*** We cannot over-emphasize that the transmission fluid should be checked with the gear selector in Neutral. With the vehicle in Park, there is no fluid flow! Hence, if you take a transmission fluid level reading with the vehicle in Park, the reading will always be higher than it actually is. Additionally, should your transmission fluid become too hot, shift the transmission to Neutral—not Park—to ensure that there is fluid flow and thus the opportunity for fluid cooling.